Why Is Your Electronic Contract Manufacturer Not Shipping Ontime?

Running out of parts during a PCB assembly run is one of the most common reasons for shipping late. Whenever that happens a decision must be made depending on parts availability:

1. Continue running the boards and hand place the missing parts later when they become available. This option is feasible if the number of boards is small and if the parts are easy to place by hand.

2. Stop the SMT line, order more parts and wait for the new parts to arrive.

3. Tear down the feeders and switch to another job until the parts arrive.

Does ordering enough extra parts solve this problem?

You should always order enough extra parts but that alone will not solve the problem. Too often electronic contract manufacturers do not receive all the parts they were supposed to… The quantity that is in the bag is not necessarily the quantity that is printed on the label.

Do the parts always have to be counted before running a job?

Yes, they do to make sure you do not run out of parts during a PCB assembly run. Unfortunately, most electronic contract manufacturers don’t because it is too tedious without an X-Ray Electronic Component Counter.

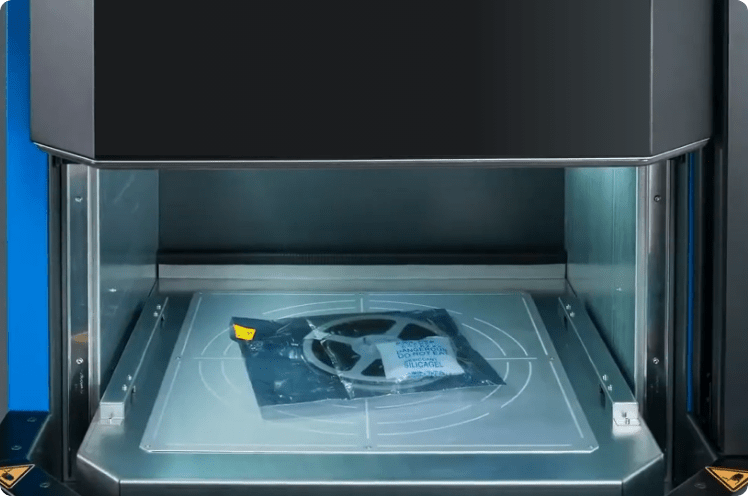

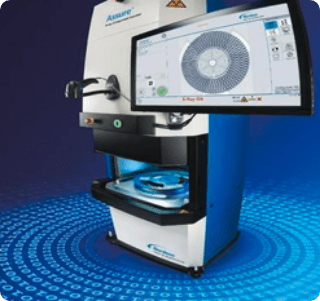

What is an x-ray electronic component counter?

An X-ray component counter is a sophisticated device used in PCB assembly to count electronic components, particularly those stored in reels, trays, or tubes. These machines use X-ray technology to see through packaging materials and accurately count the components inside without opening the packaging.

Benefits of using X-ray Electronic Component Counters:

High Accuracy and Precision: X-ray component counters provide highly accurate counts, reducing errors associated with traditional counting methods. This precision is crucial for inventory management, preventing shortages or excesses in stock.

Non-Destructive Counting: X-ray technology allows for the counting of components without unpacking or damaging the packaging, preserving the integrity of the components.

Speed and Efficiency: Capable of counting thousands of components in a matter of seconds, greatly enhancing productivity and reducing labor costs.

Versatility: Can handle a wide variety of component types, sizes, and packaging formats (reels, trays, tubes, etc.).

Data Integration: Many X-ray component counters come with software that integrates with inventory management systems, providing real-time data and analytics. This integration facilitates better tracking, reporting, and decision-making.

Automated Reporting: Generates detailed reports and logs, which can be used for inventory management, auditing, and quality control.

Improved Inventory Management: Ensures accurate inventory levels, preventing overstocking and stockouts, which helps optimize supply chain management.

Enhanced Production Planning: Provides precise component counts that assist in accurate production scheduling and planning, leading to more efficient manufacturing processes.

Cost Savings: Reduces labor costs associated with manual counting and minimizes errors that could lead to costly production delays or defects.

Quality Control and Compliance: Supports quality assurance by ensuring that the correct number of components is used in production which is critical for quality control. This accuracy helps meet regulatory requirements and industry standards, ensuring compliance.

Reduction in Waste: Accurate counting minimizes material waste and ensures that components are used efficiently.

Enhanced Traceability: X-ray electronic component counters often include features that enhance traceability, such as barcode scanning and data logging. This traceability is vital for tracking component batches and maintaining detailed records for quality assurance and accountability.

PCB Assembly Express is a full-service electronic contract manufacturer (ECM) located in Tualatin, Oregon. We are constantly investing in the latest technology because we are committed to meeting your lead-time and quality requirements. You can quote your PCB Fabrication, PCB Assembly and Electronic Components Online or send your files to support@pcbassemblyexpress.com for a custom quote.

LEAVE A REPLY